MPU 200 is used as a functional filler in the manufacturing of Polyurethane Slabstock foams. MPU improves technical parameters and reduces variable costs in foam manufacturing.

MARKETS FOR MICRONIZED POLYURETHANE

WOOD COMPOSITES

MPU 300 enables the substitution of up to 30% of conventional pMDI in OSB manufacturing without impacting technical parameters and by reducing variable costs.

CONSTRUCTION CHEMICALS

MPU 150 and 170 may be used in various construction chemical applications such as water-proofing membranes, tile adhesives (CBTA) or as a light weight aggregate.

A NEW LEVEL OF INNOVATIONS

Markets for MPU do not exist, they need to be created. In traditional industries with long innovation cycles this is an ambitious goal. In our target market segments, we are reaching out to the pioneers and are offering them our collaboration to prepare new grounds. Our partners differentiate not only through their commitment to sustainability and circular economy but also by their high levels of innovation power and progressiveness.

POLYURETHAN SLAPSTOCK FOAM

MPU is used as a functional filler in the manufacturing of polyether slabstock manufacturing. In this application, requirements for feedstock into the recycling process are delicate. Only selected sources of industrial waste are recycled and all our MPU’s are enabling the production of foams according to Certipur standards when formulated with a 15-20 pphp MPU loading.

In addition to the ready to use MPU products, Mobius is supplying suitable machine technology to dose, mix and introduce our products into the customer process.

The use of MPU 200 in slabstock manufacturing enables not only the reduction of variable costs, it is also leads to increased foam hardness and to a better comfort factor. In addition, MPU is reducing the exothermal reaction in the foaming process.

Learn more about the opportunities of MPU in slabstock manufacturing and order our detailed brochure.

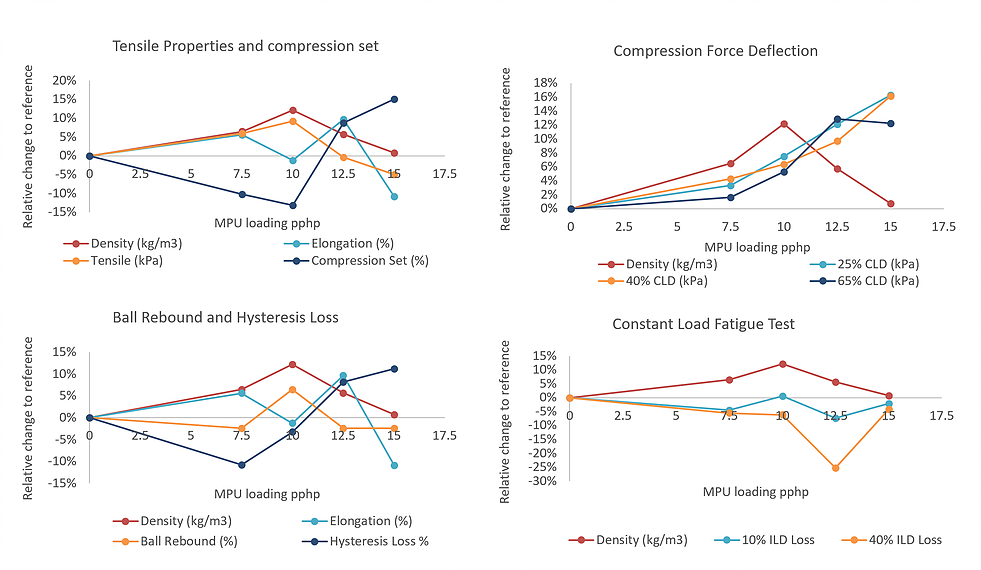

The graph above shows technical values of a 25 Kg/m3 foam as a function of the MPU loading.

WOOD COMPOSITE INDUSTRY - OSB

For more than 10 years, Mobius delivers the wood composite industry with MPU products as a substitute for conventional pMDI. MPU is a system solution for the OSB (Oriented Strand Board) industry consisting of the recycled polyurethane and the machine technology for dosing and feeding into the existing process. IMAL and Coil blending systems can be supplied with our technologies..

In manufacturing of OSB 3 panels, MPU can substitute up to 30% of pMDI in the surface layer and up to 20% in the core layer. To enhance reactivity, core layer products are coated with a suitable catalyst.

We may count the larger part of the European OSB industry to our solid customer base.

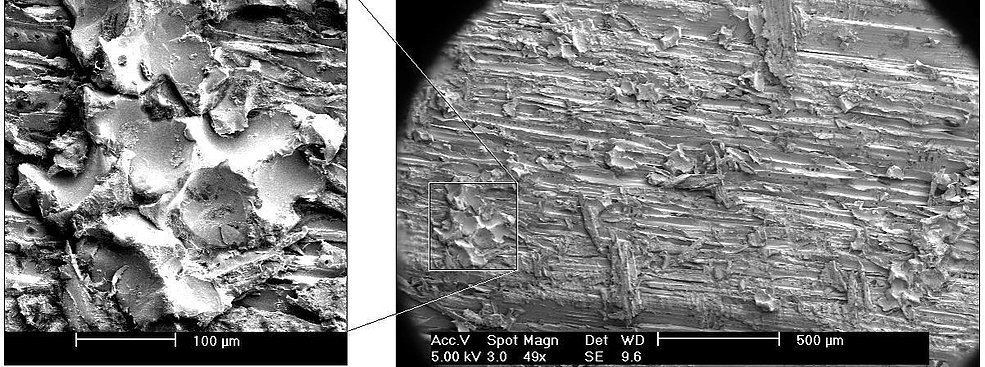

The picture above shows the point of rupture in the joint of lignocellulose structure in solid wood. The MPU particle is well visible.

Learn more about MPU in this application and order our detailed brochure.

CONSTRUCTION CHEMICALS

For applications in construction chemicals the unique properties of MPU are used in numerous ways. MPU is used for viscosity control of liquids, as matting agent in paints or to improve cohesion of Cement Based Tile Adhesives (CBTA).

The current focus of Mobius R&D efforts in this market segment lies on MPU as a light weight aggregate and as fictional filler in water proving membranes.

de

de en

en